ETHER METALIKA PRIVATE LIMITED

Discover the complete story of Ether Metalika Private Limited through our detailed company profile.

Learn about our mission, vision, and the values that drive us to deliver world-class products.

Explore our extensive infrastructure, modern facilities, and state-of-the-art technologies.

Understand our advanced manufacturing capabilities and the expertise of our skilled team.

📥 Download the PDF to gain deeper insights into how we create excellence for our customers.

THE MODERN RICE MILLING SOLUTIONS

INFRASTRUCTURE

Ether total working area 123200 sq.ft.Ether design centers are equipped with high-end servers and workstations complete with the latest CAD / Solid works software and tools.Dedicated engineering department to achieve higher yield and profitability. The service division is operated by a team of over 10 highly experienced service engineers and professionals to support our extensive client base.60000 sq.ft fabrication and manufacturing facility.1500 sq.ft paint facility.

- Manufacturing Capabilities include

- Advanced Fiber Laser machine with 6-Meter BedAdvanced

- Automatic CNC Sheet Rolling machine

- Advanced Laser Welding machine

- Precision Lathe machine

- CNC press brake

- A dedicated engineering and technical team

MISSION & VISION

Our mission is to develop the world's finest products for our customers.

Our responsibility is to serve our customers in the best possible manner and also to contribute to the cultural advancement of society.

Our duty is to see that the company and employees mutually prosper and maintain a harmonious relationship.

MATERIAL STORAGE SOLUTION

Grain storage silos are the best alternative for traditional storage systems. Our silos avoid storage losses like rodents, moisture, and insects. We design our silos based on the project requirements and provide ease of assembly, hygienic handling and use quality materials. Either silos are made of high-quality steel and high-quality metal.

ETHER METALIKA COMPLETE RICE PROCESSING

WHITENER

SATAKE innovates continuously and creates a marvel repeatedly. The New Rice Whitener is the latest in the list. This machine improvises on existing design and incorporates various improvements to suit long grain milling in a gentle manner. Most suited for sensitive Steamed Rice for Higher Welds and Parboiled Rice for Low Temperature Milling

POLISHER

The SATAKE KB Rice Polishing Machine cleans the surface of rice, significantly enhancing the quality of finished products.

The machine has achieved a high reputation in many countries for its high performance and for the innovations which have been incorporated over the past 25 years

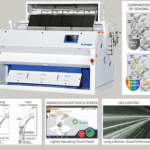

COLOR SORTOR

Improved Performance

The New Optical Sorter further enhances sorting performance for both ACCEPT and REJECT grains with improved CCD cameras and a more accurate rice-center ejecting function. The ejectors and internal structure have been optimized to improve sorting performance and throughput capacity.

ASPIRATION DUCTS

Aspiration ducting in a rice mill is a system of pipes and ducts connected to blowers or fans, designed to create suction (negative pressure).

This suction removes lightweight materials – like

ACCESSORIES

Cyclone

Slide Gate

Cyclone Air Lock

Magnetic Separator

Elevator Bucket

IN HOUSE ELECTRICAL PANEL MAKING

A rice mill panel board is an electrical control system that manages the various processes within a rice mill, from intake to packaging. It can be a simple starter panel or a more complex PLC (Programmable Logic Controller) panel that automates and controls numerous functions.